- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

Plastic Bag Production Line

MQ-Plastic bag machine manufacturer,also advocates protecting the environment and using cloth bags.

Film blowing machine :

The first step is to process plastic raw materials into plastic films, and use a film blowing machine to cut and roll them for the convenience of subsequent secondary processing.

The extruder, barrel, screw are made of high quality alloy steel, tight nitriding treatment and precision machining, with the best hardness and corrosion resistance, specially designed screw production is high, good plasticizing. Suitable for blowing low density polyethylene (LDPE) high density polyethylene (HDPE) linear low density polyethylene (LLDPE) (PLA) and other plastic film, widely used in food, clothing, garbage bags, vest bags and other civil and industrial packaging.

| Model | MQ-FB50 | MQ-FB55 | MQ-FB60 | MQ-FB65 |

| Material | All | All | All | All |

| Film diameter | 600mm | 800mm | 1000mm | 1200mm |

| Film thickness | 0.008-0.15mm | 0.008-0.15mm | 0.008-0.15mm | 0.008-0.15mm |

| Max extrusion | 35kg/h | 55kg/h | 65kg/h | 80kg/h |

| Gear box | 133 | 146 | 173 | 180 |

| Screw diameter | φ50 | φ55 | φ60 | φ65 |

| L/D | 28:1 | 28:1 | 28:1 | 28:1 |

| Screw material | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA |

| Drum material | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA |

| Main power | 11kw | 15kw | 18.5kw | 18.5kw |

| Die mouth | φ50, 100 | φ100,150 | φ150,200 | φ200,250 |

| Cooling fan | 1.1kw | 1.5kw | 1.5kw | 2kw |

| Traction roll width | φ150*650 | φ150*850 | φ150*1100 | φ150*1300 |

| Embossing roll wide | 550mm | 850mm | 1100mm | 1300mm |

| Draw motor power | 1.5kw | 1.5kw | 1.5kw | 1.5kw |

| Extraction speed | 10-60 m/min | 10-60 m/min | 10-60 m/min | 10-60 m/min |

| Winding width | 700mm | 900mm | 1100mm | 1300mm |

| Coiling power | 6N | 10N | 10N | 10N |

| Floor area | 5*2.2*4.2m | 5*2.4*4.8m | 6.5*2.3*4.9m | 6.5*2.5*5.6m |

Other sizes, widths, can be customized.

· The model of the film blowing machine is determined according to the width of the blown film, which is generally divided into 600mm, 700mm, 800mm, 900mm and 3000mm,

· The model can be selected according to personal needs, what kind of film to produce and how wide the film is. The price of the machine depends on the model and machine configuration.

· Before purchasing, you can contact the sales consultant online to tell the salesperson your needs and what model you plan to equip, so that the salesperson can help you choose the model that suits you.

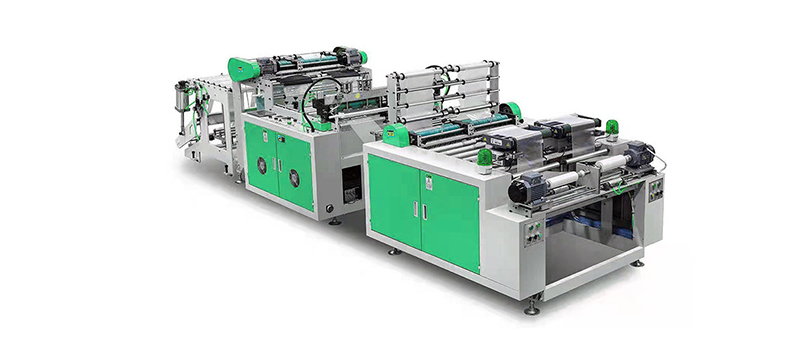

Bag making machine:

This machine is equipped with photoelectric eye tracking, the host frequency conversion speed regulation, stable operation, and high bag making accuracy. With various automatic protection functions such as overload, overvoltage and overcurrent, the automatic counting device can set the number of batches and sheets at will. It is the ideal equipment for making flat bags and vest bags (vest bags).

| Bag width | 100-350mm×4 |

| Bag width | 100-800mm |

| Bag length | 100-1200mm×4 |

| Production speed | 40-120pc/min×4 |

| Film thickness | 0.01-0.08mm |

| Power | 5kw |

| Machine weight | 1300kg |

| Overall dimensions | 6500×1350×2000mm |

Other sizes, widths, can be customized.

This machine with HDPE, LDPE cartridge film as raw materials can produce printing, color, vest bag, using PLC control, double servo (stepping) motor fixed length, LCD touch screen real-time display, from the feeding, cover, cutting, punching, conveying one-time completion, high degree of automation.

·This machine is a special machine for vest bag hot air heater, which can automatically double line punching, increase output and save manpower.

·The machine is double rail, double production lines, double printing bags and double stepping (servo) motors.

·Electric eye inductive tracking, accurate printing pattern, automatic stop warning when the electric eye fails.

·The cooking motor is controlled by frequency converter, which is easy to operate and reduces power consumption.

·No material automatic stop device.

·When the machine reaches the set number of sheets, the punching machine can immediately clamp the bag and continuously feed materials without stopping.

·With the newly designed sealing knife structure, when the sealing knife needs to be cleaned, it can be fixed by reversing the sealing knife 180 degrees for cleaning, which is safe and reliable and easier to maintain.

·Out of the bag shall be neat and the sealing shall be firm.

·The pneumatic hydraulic booster cylinder punching machine is adopted, which has low noise and low air consumption.

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD