- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

3D Filament Extruder

MQ-Filament machine expert!

3D Filament extruder is very important.

3D printing is a revolutionary technology in recent years.3D printing has been became more and more popular for all kinds of industries.

The most common is the proofing of industrial parts. The performance of 3D printing is excellent, which can save 50% of the proofing time. At the same time, with the improvement of 3D modeling technology, 3D printing has entered thousands of households.

Therefore, in the future, every industry will involve 3D printing.

Save the time you choose:

1Big capacity compared with other suppliers using the same model.

2Perfect tolerance: +/-0.03mm, even+/-0.02mm.

3Can produce the different diameter of filament from 1 .5mm~3.0mm.

4Easy operation: PLC full-automatically control system.

5Produce different raw material: ABS PLA PEEK PET PA HIPS PVA,etc.

6Low maintain. We dont receive any complaint once the machine isrunning.

7In order to ensure the quality, components of global first-line brands such as use Siemens, ABB and Schneider.

3D Filament extruder process:

Mixer machine→Vacuum loader→Hopper dryer→Single screw extruder→Die head→Hot air cooling or water tank cooling→Tractor machine→Storage thread stand→Laser measuring diameter instrument→Rolling up machine→Vacuum packaging machine

3d Printing filament machine:Type:

Top 3d printer filament making machine designer and manufacturer, features of smallest tolerance, stable filament extrusion, advanced neat filament winder technology.

| Model | Power | Diameter | Output | Tolerance(mm) |

| MF16 | 300w | 1.75~3mm | 0.5~2kg/h | ±0.05mm |

| MF20 | 400w | 1.75~3mm | 2~6kg/h | ±0.03mm |

| MF35 | 4kw | 1.75~3mm | 8~16kg/h | ±0.03mm |

| MF45 | 7.5kw | 1.75~3mm | 18~30kg/h | ±0.02mm |

| MF65 | 15kw | 1.75~3mm | 30~50kg/h | ±0.02mm |

◇◇◇◇◇◇

MQ-Teach you to choose raw materials:

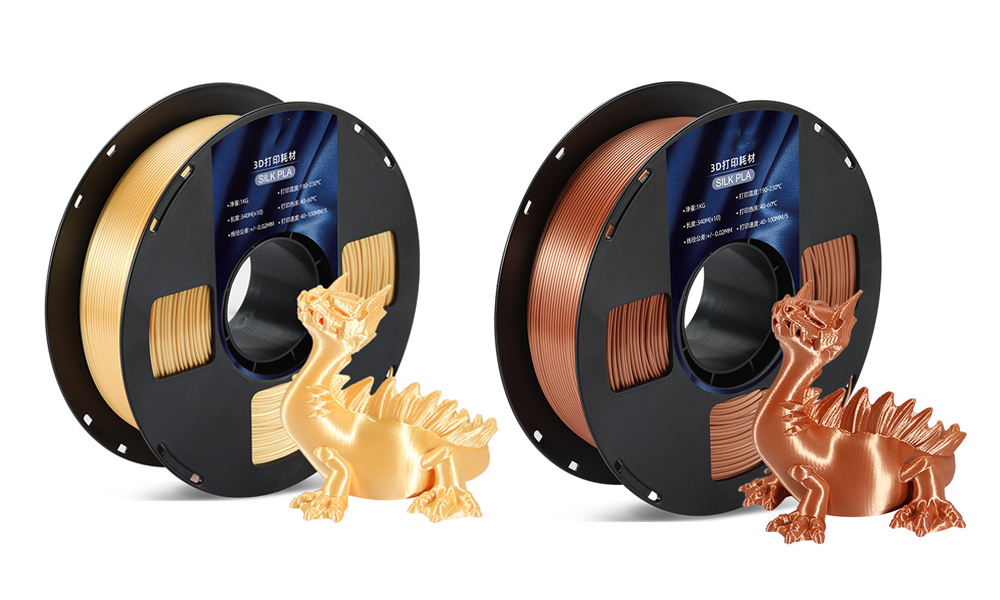

Common materials for 3D printers on the market include PA, TPU, PETG, PLA,PEEK,PVA and ABS,and so on. among which PLA and ABS are the most commonly.PLA: polylactic . This kind of material is the most commonly used 3D printing consumables for the public. It can be said that due to the characteristics of PLA, it can be printed at any time. However, it should be noted that such consumables are brittle and will deform when the temperature is too high.

For example:PA

Nylon, also known as polyamide, is a kind of resin with strength, toughness and flexibility. This type of consumables is a heavyweight champion in the 3D printing industry and a synthetic polymer commonly used in many industrial applications. Compared with other consumables, it has the characteristics of high strength, high toughness, wear resistance, flame retardancy, etc., and its dyeable according to user preferences.

For example:PLA

Polylactic(biodegradable) . This kind of material is the most commonly, use3D printing consumables for the public. The reason why widely accepted and commonly, use by the public is that it is easy to print, easy to form, odor free, and more environmentally friendly. Due to the characteristics of PLA, can printing at any time. However, it should be noted that such consumables are brittle and will deform when the temperature is too high.

For example:ABS

Acrylonitrile butadiene styrene is also the third most commonly used 3D printing consumables after PETG and PLA. Its advantage is that the printed products have high strength, better durability and high temperature resistance. Most importantly, Can recycle it. The only biggest problem is that it will have an unpleasant smell when used, so you need to pay more attention to ventilation when using such consumables.

For example:PETG

Polyethylene terephthalate. This kind of composite material combines the advantages of PLA and ABS materials. Compared with ABS, it has higher toughness, and is easier to print than ABS, without edge warping, odor and steam drum. At the same time, its printed products are transparent, and it is one of the most favorite 3D printing consumables in the advertising word industry.

For example:TPU

Thermoplastic polyurethane is a special soft material. The finished product printed with TUP has certain elasticity. It is also a popular 3D printing consumable, mainly because of its good printing effect: no warping and bubble, smooth and delicate printing effect, and accurate color. Another feature is that it is an environmentally friendly product, non-toxic and non irritating smell.

3D Filament extruder

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD