- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

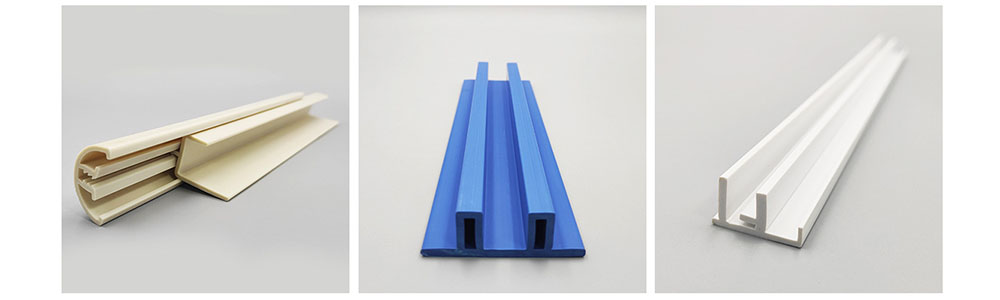

Plastic profile making machine

What is plastic profile?

Plastic profile making machine, Profile: such as window frames, stair handrails, cable trays, track strip,Heat insulation strip,hardware attachment strip,baseboards, shaped pipes, furniture, and building materials. The main raw materials are hard PVC, soft PVC, polyurethane low foaming materials, PP,PE,ABS,etc.

The MPP series profile production line, main use for producing door and window profiles, sealing strips, etc. This production line can choose different specifications of extruders according to different profiles and molds, and There are more auxiliary devices, such as vacuum shaping tables, traction machines, cutting machines, and flipping platforms.

Plastic profile extruder model

Production process:

Plastic profile production line, the most important is mold and shaping.The development and design of molds require accurate drawings, and the best scheme is buyer provide.In addition, it is also necessary to combine raw materials, because there are factors such as expansion degree and deformation rate.

Mold head part: After compaction, melting, mixing and homogenization, subsequent materials are pushed towards the mold head by screws, and the extrusion mold head is a crucial component for profile forming.

First of all,Feeding system; Then,extruder(Melt plasticizing);Mold (initial molding);Water jet cooling;Conveying, Cutting.

| Model | Diameter | Output | Raw material |

| MPP45 | 45mm | 60~150kgh | Support all |

| MPP65 | 65mm | 150~250kgh | Support all |

Plastic profile equipment Advantage

Use widely,Decoration, living, construction, equipment,All require profiles.

Stable equipment and mature technology.

Low machine prices and high return on investment.

Door-to-door installation, and 7*24h After-sales service.

Provide online technical support and experimental formula.

Raw materials

Common include:PVC,ABS, PE+Wood, PVC+Wood, PE, PP, PE+CaCo3, TPU,PA+GF,TPV,etc.

First, from powder to pellets,use twin-screw pellet extruder modify and compound.

Then go to the profile production line,Made into sealed lines, etc.

Reference formula:

30~35% PE(MI≤2)+60~70% Wood powder(40~80mesh)+5~10% Calcium carbonate(1000mesh)+4~4.5% Auxiliary agent(LEPHD/LEPHF)+0.2% UV531+0.2% Antioxidant(1010)+0.2% Antioxidant(AT186)

100% PVC (k=57~60)+40% Wood powder+1.5% AC(Azodicarbonamide)+2% Coupling agent+2% Calcium stearate+10% Plasticizer+2% paraffin Wax+0.2% Antioxidant(1010)+0.2% Formaldehyde+3% Additive Ant prevention

Of course, you can also choose to purchase pellets directly.

Related:Plastic profile making machine,Wood plastic flooring production line,Twin screw extruder,Sealing strip machine,Wall panel machine.

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD