- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

Plastic Extruder Barrel

As plastic extruder barrel / cylinder, there are different models and types available.

So,Let’s learn more about extruder screw and barrel.

Then,common extruders: 1.Single screw extruder 2.Twin screw extruder 3.Triple screw extruder

Extruder barrel

Plastic extruder barrel classification: 1. Open barrel 2. Closed barrel 3. Liquid injection barrel 4. Side feeding barrel 5. Extruder cylinder 6. Special custom

Meanwhile, can use barrel in plastics industry, chemical, food industry. Barrel “building block” design, so worn screw and cylinder components can be partially replaced, avoiding the scrapping of the entire screw or cylinder and greatly reducing maintenance costs.

Of course, there is a waterway design inside the barrel to ensure that while heating, it has the function of cooling and maintain the accuracy of the temperature.

Therefore, under each cylinder, there will be holes for thermocouples to observe the temperature in each zone. Cylinder heating: heating plate external heating and internal heating tube heating.

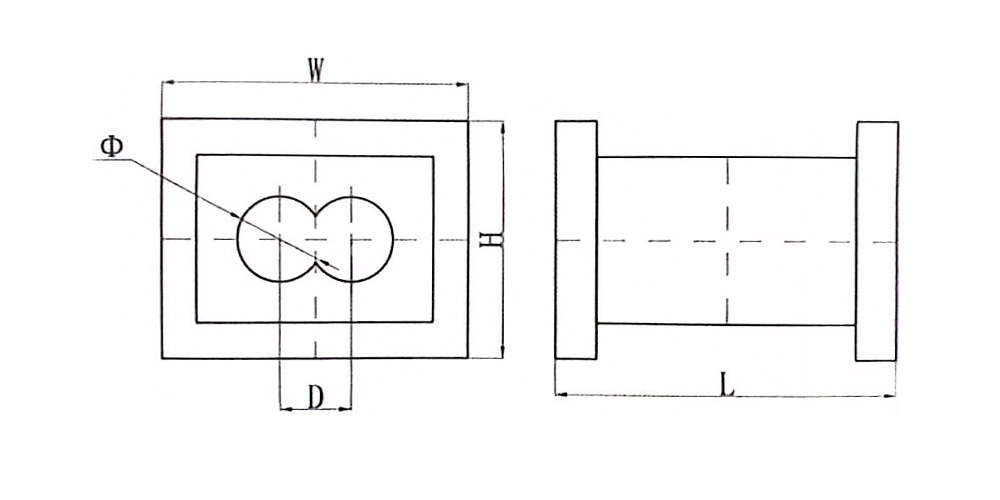

Barrel size

| Model | Dimension (L*W*H) mm | Inner Diameter mm | Distance Center mm |

| 20 | 132*115*105 | 23 | 18.4 |

| 36 | 150*160*140 | 35.6 | 26 |

| 40 | 160*170*145 | 41.6 | 34.5 |

| 50 | 190*190*150 | 51 | 42 |

| 52 | 210*200*155 | 52 | 43 |

| 60 | 240*210*170 | 60 | 52 |

| 65 | 240*210*170 | 63 | 52 |

| 75 | 290*260*200 | 71.8 | 60 |

| 85 | 320*280*215 | 81.9 | 67.8 |

| 92 | 360*310*240 | 92 | 78 |

| 95 | 360*310*240 | 94 | 78 |

| 110 | 420*330*240 | 109 | 91.5 |

| 125 | 500*390*290 | 125 | 98 |

| 135 | 520*440*340 | 134 | 110 |

Production process and material

Forged metal germ→Rough machining→Finish machining→Barrel inspection, more than 25 processes.

The main material is 45# alloy steel and 38CrMoAL, Sleeve: а101alloy, HRC58~62.

Corrosion resistant materials: hastelloy.

Non-standard barrel / cylinder can be customized, cycle 7~60days,custom need drawing.

Our advantage

- Structural design is conducive to material forming and preventing scorch or bonding

- High mild alloy steel, quenching process, wear resistance

- Perfect mixing effect and self-cleaning

- Low maintenance cost, simple maintenance

- 7*12h Online service

Search

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD