- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

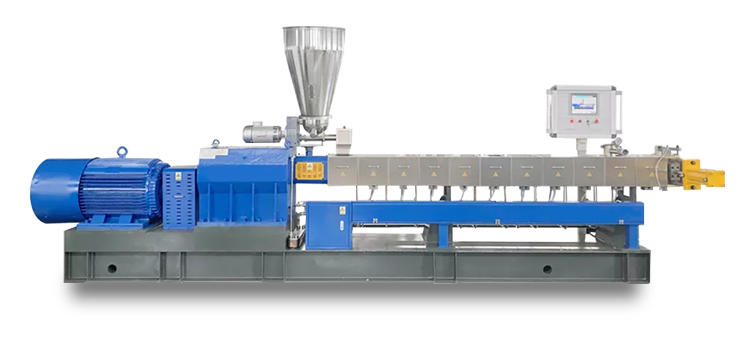

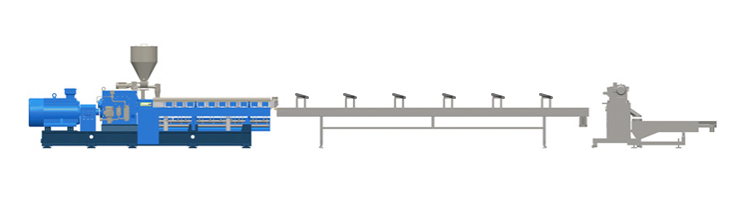

Plastic Granulator

About plastic granulator,there are single screw and twin screw.

Using single screw extruder , it is common to recycle plastic. And using twin screw, resin filling, blending, modification, compounding and so on.

The barrel and screw of the parallel twin screw granulator, according to the building block principle. And different combinations can be made according to needs.

How to choose plastic pellet machine?

We supply turn-key solutions to your compounding projects. Therefore, includes material handling, dosing, extrusion, pelletizing and other aspects.

You can use them for lab purposes or large production. From lab scale extruder to big twin screw extruder, you can always find what you need.

Therefore, the most important thing is capacity and raw material type.

So, Here are the parameters:

Plastic granulator data

| Model | Diameter(mm) | L/D | Motor(kw) | Output(kg/h) |

| MT20 | 21 | 24~48 | 4 | 5~15 |

| MT36 | 35.6 | 24~64 | 22 | 70~100 |

| MT50 | 50.5 | 24~64 | 75 | 150~250 |

| MT65 | 62.4 | 24~64 | 90 | 250~400 |

| MT75 | 71 | 24~64 | 132 | 450~650 |

| MT95 | 93 | 24~64 | 250 | 750~1200 |

Twin-screw plastic granulator technology

(1) Conveying section, conveying materials to prevent overflow.

(2) The melting section, which makes the material fully melt and homogenize through heat transfer and friction shear.

(3) Mixing section, so that the size of the material components is further refined and uniform, forming an ideal structure, with distribution and dispersion mixing function.

(4) Exhaust section, discharge water vapor, low molecular weight substances and other impurities.

(5) The homogenization (metering) section, conveying and pressurizing, establishing a certain pressure, so that the material at the die has a certain density, while further mixing, and finally achieve the purpose of smooth extrusion granulation.

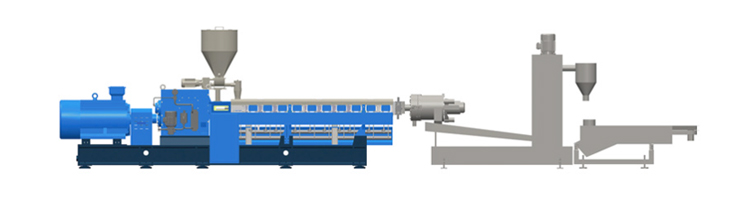

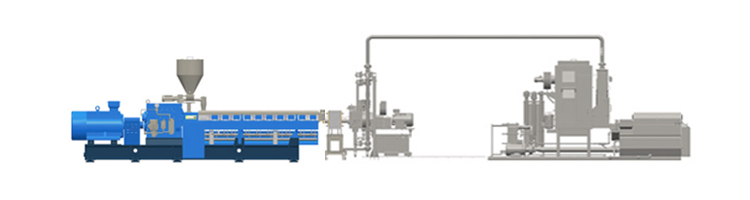

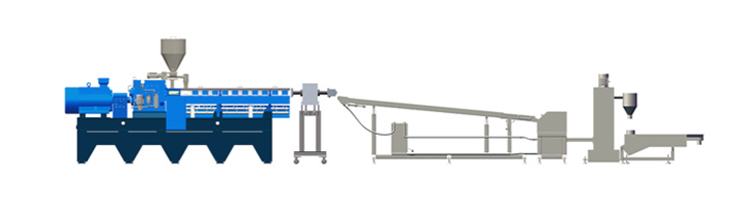

Plastic pelletizing System

plastic pellet machine need a cooling and cutting system for complete production line.

Every compounding process is specific and distinct. Can help you design the right solution for you.

Water Cooling Strand Pelletizing System

Water Ring Pelletizing System

Underwater Pelletizing System

Water Strand Flow Pelletizing System

Air Cooling Strand Pelletizing System

Air Cooling Die Face Pelletizing System

Extensive Experience in Applications

MQ has delivered more than 200 sets extruder machines.

Our twin screw compounder can be widely used for:

Filler Masterbatch, Color Masterbatch, Additive Masterbatch, Biodegradable Plastic, Cable Compounding, Engineering Plastics Reinforcing (GF), Aerospace PEEK carbon fiber, PVC Compounding, Biodegradable plastics, Polyolefin Compounding, Reacting Direct Extrusion, Thermoplastic Elastomers,PET pelletizing and other plastic such as Nylon, PE, XLPE, WPC, LCP, PPSU, PTFE, ect.

After more than ten years of precision research and innovation, we have formed a complete set of fully automatic polymer processing production lines based on twin-screw extruders, as well as independent production of high-end key parts.

Our advantage

- Accurate temperature, error less than 1℃

- Precision pressure sensor and pressure alarm system

- Wear-resistant screw and barrel

- Simple operation, easy to clean

- First-line brand electrical components

- Support all countries, installation and after-sales

- Consultation service time: 7*12h

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD