- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

Pelleting System

MQ-15 years of experience, plastic extruder machinery industry leader.

Every compounding process is specific and distinct.According to different materials, different formulations,different extruders,choose the most cost-effective pelleting system.

There is no perfect pelletizing machine, only one that is most suited for you.

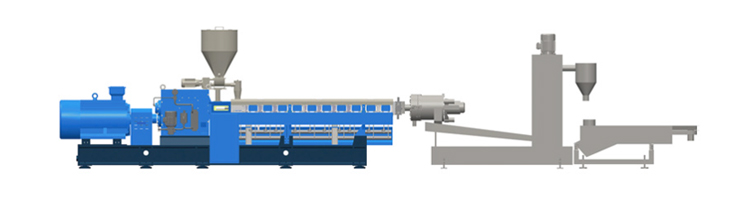

Water Cooling Strand Pelletizing System

It is suitable for most polymer compounding production, which features simple structure, easy operation and convenient maintenance. Easy to use and easy to maintain.The threshold of operators is also low. This system consists of strand die, water batch, air knife, strand pelletizer.It’s the most cost-effective pelleting system.The granules produced are small cylinders.

Pelletizer power: 1.5KW. 2.2KW, 3KW.

All the water will be removed and stored in one stainless steel tank.

All the parts touching with material is made of stainless steel.

Water Ring Pelletizing System

It is suitable for certain recipes, such as PE/PS/EVA/TPU etc. Final pellet looks nicer and has good flowability. The length of production line is shorter than that of strand pelletizing.Long service life, low cost.The granules produced are small ellipse.

This system includes water ring pelletizer, water circulating system, centrifugal dewater and vibrating classifier.

Driving power: 2~3KW.

RPM controller: AC inverter.

The cutter shaft is moved by pneumatic.

With 4 pieces of cutting knives.

S.S. for cutting hub.

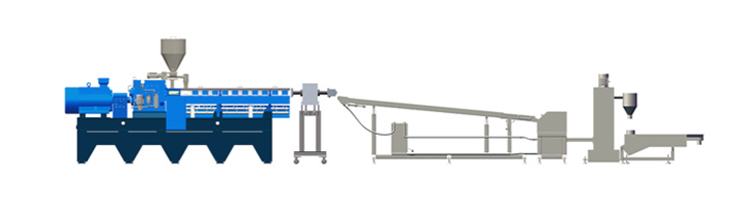

Water Strand Flow Pelletizing System

This system is suitable for plastic recycling which needs to change the filter frequently. Strands go into the pelletizer automatically by the water flow, even the strands break during changing the filter. So there will be almost no waste during the manufacturing process. The granules produced are small cylinders.

This system consists of strand die, water bath, strand pelletizer, centrifugal dewater and vibrating classifier.

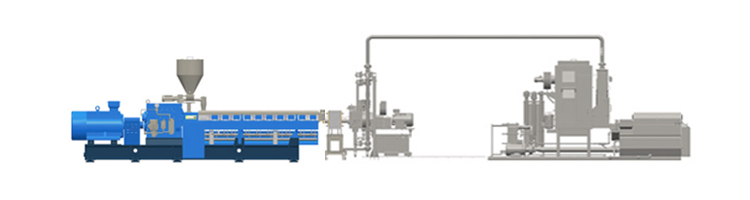

Under-water Pelletizing System

This system is suitable for most polymers. Especially for TPU and TPV or similar elastomer, its advantage amplifies. Comparing to other pelletizers, underwater pelletizing system is more compact which is obvious when output is immense. The size of final pellets can also be controlled in a finer manner.Pellets are shaped like pills.It’s the most expensive pelleting system.

This system consists of die heads, underwater pelletizers, water circulating system, and dewater system. It can also be incorporated in an auto-packaging system.

Die plate heating: eletrcial heater or Oil

Two type of knife: bevel and vertical. It is designed for different material.

Two type of pressure setting for knife: Manually and Hydraulic.

Online polish for knife

One button start/stop

Knife length indication

With hydraulic station, the knife pressure can be setting on the touching screen, and the system will regrind knife automatically according to the setting time and pressure.

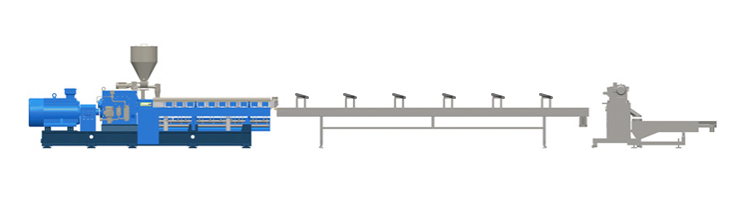

Air Cooling Strand Pelletizing System

This system incorporates a single stage extruder. It is suitable for certain recipes, such as PP base filler degradable and starch and CaCo3 and WPC/PLA/PBAT/PBS, because its highly tenacious trait prevents it to be cut by the air-cooling die face pelletizer. The other merit of this system is that it prevents the materials from encountering water.The granules produced are small ellipse.

This system includes die heads, air cooling belt conveyor, strand pelletizer and vibrating classifier.

Pelletizer power: 1.5KW. 2.2KW, 3KW

Conveyor belt length:15~30meter

A fan is installed every 1 meter

Air Cooling Die Face Pelletizing System

This system incorporates a tandem compounder. It is suitable for certain recipes, such as PVC, LLDPE, high filling masterbatch, degradable masterbatch, HFFR, WPC etc., which have a ring type and centrifuge type as per the property of the raw materials. The merit of this system is that it prevents materials from encountering water which is critical for certain materials.Granules like drug tablet shape.

This system includes die heads, air cooling pelletizer, air cooling conveyor and vibrating classifier.

Driving power: 1.5KW, 2.2KW, 3KW.

RPM controller: AC inverter.

With 4 pieces of cutting knives.

S.S. cover with water jacket for cooling.

Stainless steel cover.

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD