- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

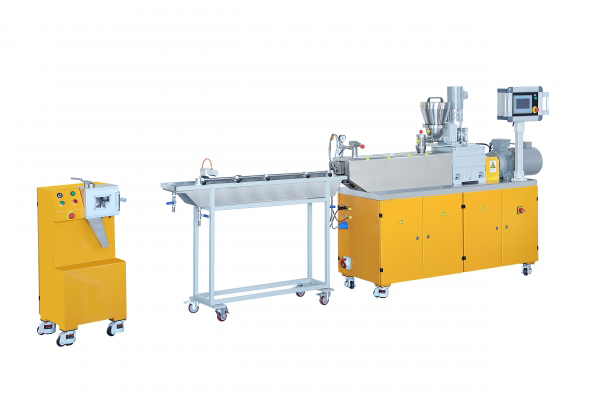

Lab Plastic Pelletizer

Lab plastic pelletizer is specially designed for the trial-level or entry-level user, or the small scale production.

Modular design makes it very flexible against different formula.More for the design and development of new materials,in universities and chemical companies.

About small plastic compounding machine

First of all, the selection of small granulator, after confirming the formula, the introduction of large production lines.

Therefore, granulation and composite are the starting point and basis of plastics.

Lab twin screw extruder include compounding, direct extrusion, degassing (devolatilization) and reaction extrusion, and support multiple raw materials.

Use it for stimulate the continuous extrusion process for batch samples, new material research, new process development and small quantity production.

Our compacted lab plastic pelletizer: integrate mechanical parts and electrical parts together, which is followed plug-in concept, like home appliance.

Lab lastic pelletizer data

| Model | Diameter(mm) | L/D | Motor(kw) | Output(kg/h) |

| MT16 | 15.6 | 11:1 | 1 | 0.3~4 |

| MT21 | 21.7 | 28~48 :1 | 4 | 5~15 |

| MT25 | 25 | 28~48 :1 | 7.5 | 15~30 |

| MT36 | 35.6 | 28~56 :1 | 22 | 60~100 |

Parallel Laboratory/small plastic pelletizer product performance:

1.Split open barrel and building block screw structure, convenient and quick process adjustment

2.Quick-opening head and net changer, fast cleaning and net change

3.Touch screen and siemens PLC centralized control system, high intelligence, easy to operate

Application range of laboratory parallel twin screw extruder:

1.General plastics, engineering plastics, elastomers and other materials mixing, mixing extrusion granulation

2.Blending modification and reactive extrusion of composite materials

3.High efficiency mixing of polymer alloy

4.Polymer filling enhanced modification

Our advantage

1.Temperature accuracy: tolerance ≤1℃

2.Maximum temperature: 400℃

3.Pressure sensor accuracy: 0.2%F.S

4.Support OEM

5.Short production cycle

6.Simple operation

7.Support online services 7*12h

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD