- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

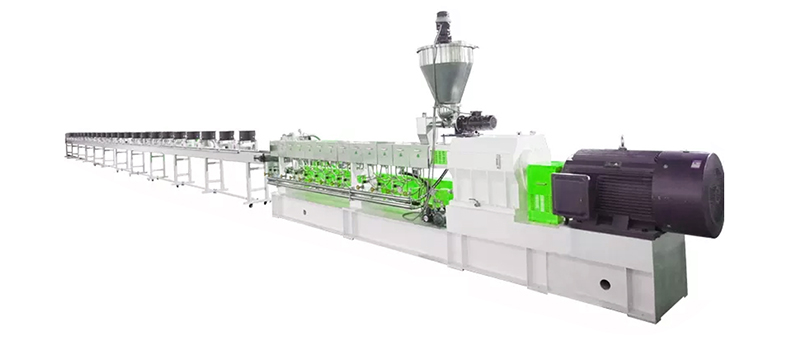

Biodegradable Granules Extruder

Biodegradable granules extruder: product Bio pellet materials that can be broken down into low molecular compounds by microorganisms in the natural environment.

Every year, more than 1 million tons of plastic waste is causing environmental damage.

We want to come from nature and return to nature. There is only one earth, we call on the whole world, protect the green, cherish the home.

For plastics, we recommend biodegradable plastics:

Biodegradable plastic is an irresistible trend.

MQ is specialist for complete extrusion lines for bioplastics. We can provide entire plant for bio plastics extrusion & compounding.

| Model | Diameter(mm) | L/D | Motor(kw) | Output(kg/h) |

| MT50 | 50.5 | 40~60 | 55/75 | 100~200 |

| MT65 | 62.4 | 40~60 | 75/90 | 250~350 |

| MT75 | 71 | 40~60 | 132 | 400~600 |

| MT95 | 93 | 40~60 | 250 | 700~1000 |

PBAT/PLA/PBS/PHA compounding with starch/Caco3 powder,This is direct compounding which can save 40% energy and better dispersion.

Pellet production process: Raw material weighing→mixe→feeding→extruder→die head→Conveyor belt cooling→cutting

Dry starch and CaCo3 moisture.

Choosing a high mixer is more convenient for plasticizing.

Premix and long L/D for better dispersion.

Special feeder for anti-bridge.

Air cooling strand pelletizing for bio base.

Need vacuum packing system.

About the bio plastic bag project:

We should only use what we need. Education, advocacy, incentives as well as disincentives (e.g. paid plastic shopping bags) to promote this idea can be implemented.

Biodegradable Pet poop bags and garbage bags, in Europe and North America, gain favor.

Use the biodegradable granules extruder, obtain biodegradable blown film pellet.

Use the film blowing machine and bag making machine to get the corresponding bag.

Finally, use the printing press and packaging machine, complete the final process.

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD