- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

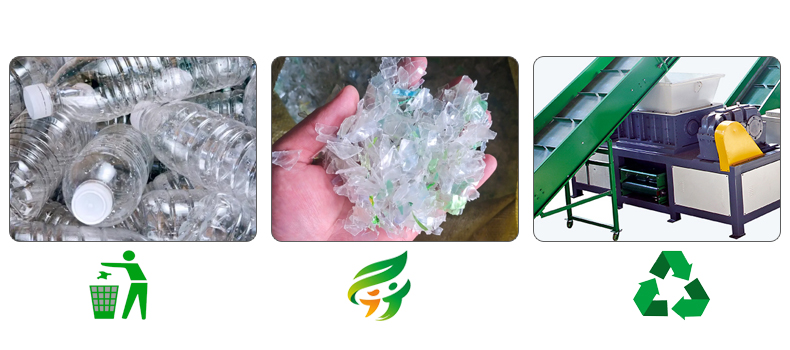

PET Recycling

About PET recycling? Polyethylene terephthalate, PET is divided into fiber grade polyester chips and non-fiber grade polyester chips.

By 2023, Polyethylene terephthalate PET bottle production capacity will reach 35 million tons.

Asia is the region with the most new bottle production capacity. Global production is expected to grow by 3-5%.

Recycling is feasible from three perspectives: profit, resources and environment.

So, pet bottle flakes recycling is very important . More conducive to the protection of the environment.

About PET Recycling

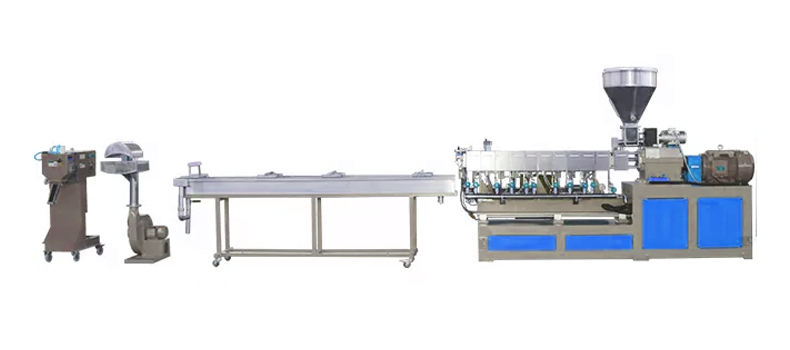

The use of twin screw and non-crystallization drying technology to recover PET, to ensure that the maintaine viscosity drop at <0.03dl/g, to achieve the original recovery of PET waste.

Streamlined Modern Process Flow

Energy Consumption saving of up to 40%

Refined Quality of finished product

Individual Solutions Geared Specifically for Recycling Tasks

| Model | Diameter(mm) | L/D | Motor(kw) | Output(kg/h) |

| MT36 | 35.6 | 38~44:1 | 22 | 60~100 |

| MT50 | 50.5 | 38~44:1 | 55/75 | 120~180 |

| MT65 | 62.4 | 38~44:1 | 75/90 | 200~350 |

| MT75 | 71 | 38~44:1 | 132 | 400~600 |

| MT95 | 93 | 38~44:1 | 315 | 700~1000 |

During the granulation process:

PET melting temperature set: aorund260 270℃

No crystallization: need larger vacuum system (can add an extra vacuum machine )

Pellet forming: Lower water temperature (Running water or chiller)

Our advantage

Has helped customers around the world successfully deploy 50 PET pelletizing lines.

PET recycling solutions involving various raw materials, such as bottle pieces, waste cloth, silk, film, sheet recycling, etc.

Among them, the PET bottle-to-bottle technology can recycle 2 million tons of drinking water bottles per year, saving 70 million degrees of electricity.

The recycling rate of PET is very high.We recommend reusing.

Higher output for low bulk density material, such as crushed cloth/yarn/fiber, BOPE film, PET sheet, bottle flakes.

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD