- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

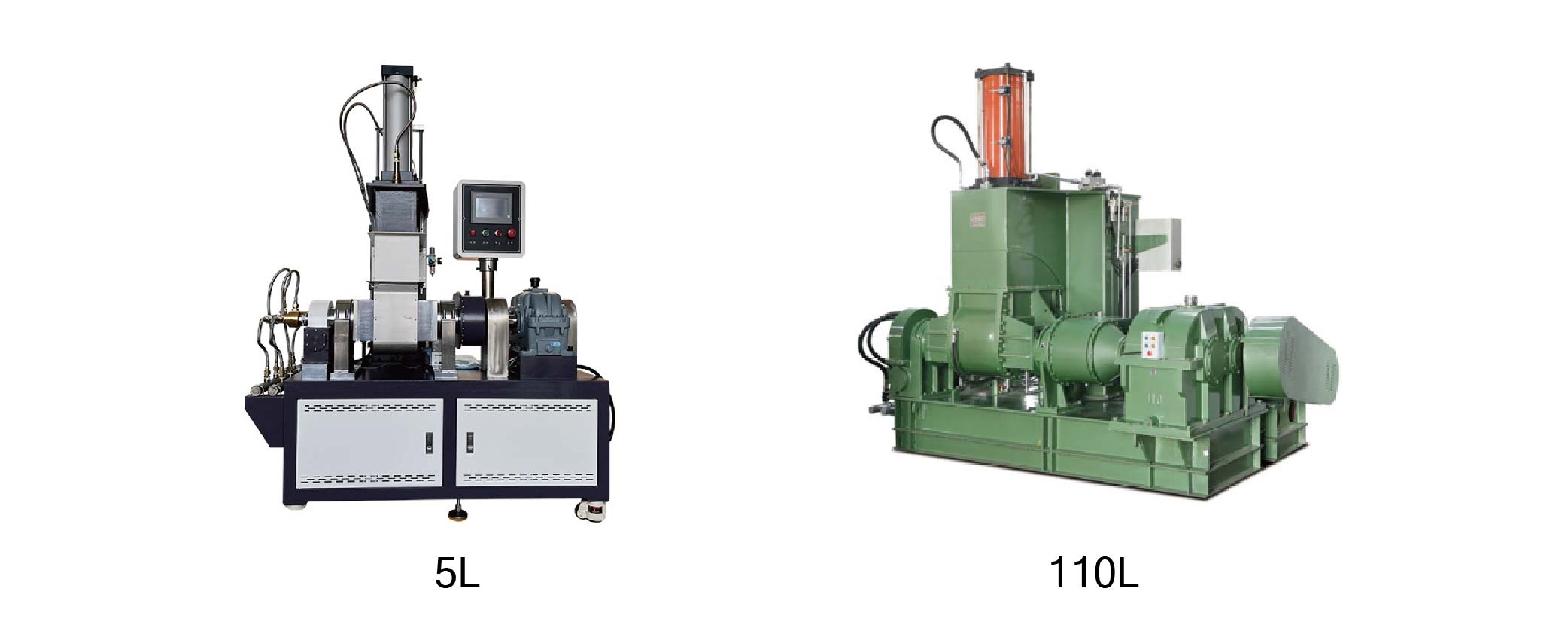

Kneader Banbury Mixer

Kneader banbury mixer plays an increasingly important role in the processing of polymer materials.

The rapid development of rubber and plastic industry and other polymer materials industry.

Therefore, plastic kneader is becoming more and more important.

SO, In particular: polymer development, plastic granulation production line, rubber production line, tire manufacturing and so on.

What is Kneader Banbury Mixer:

Plastic extrusion kneader is a type of rotor with a specific shape and relative rotation,

And mechanical process for intermittently plasticizing and mixing polymer materials in a closed state with adjustable temperature and pressure.

| Kneader Model | Volume(L) | Power(KW) | Weight(Ton) |

| MKN1 / 5 | 1 or 5 | 3 / 7.5 | 1.2 |

| MKN10 | 10 | 15 | 2.3 |

| MKN20 | 20 | 30 | 4.5 |

| MKN35 | 35 | 45/55 | 6.5 |

| MKN55 | 55 | 55/75 | 7.8 |

| MKN75 | 75 | 90/110 | 10.5 |

| MKN110 | 110 | 160/200 | 14.5 |

| MKN150 | 150 | 220 | 19.5 |

| MKN200 | 200 | 280 | 22.5 |

There are more laboratory models (0.5L, 1L, 2L, 3L, 5L, 10L), can contact us.

EVA or rubber kneader, with extruder and some vulcanization machines, making boards or tires, the process is simple.

In addition, also use plastic kneader for plastic granulator production line.

Kneader banbury mixing line:

Kneader banbury mixer—bucket conveyor —Conical twin screw force feeder—single screw extruder compound—Air Cooling Hot Face Cutting System/water ring cutting system—Silo

Kneader mixer can put all the compounding mixing them together by batch,like kneading flour again and again by inner batch.

After Banbury mix all the materials, the large HOT and SOFT mixed materials will be fed from the kneader through Bucket conveyor to the cone double force feeder.

And then push into the single-screw extruder, homogenize again and pass the materials are extrusion through the die.

Common application:

High Filler Masterbatch:PE/PP+over 85%Caco3

EVA Foam Masterbatch

Black Masterbatch

Stone Paper Masterbatch

Non-woven Masterbatch

Woven Bag Masterbatch

Plastic kneader different collocation:

Different raw materials have different characteristics,in the process of high fusion.

therefore, also need to choose more appropriate extruder, for make the particles perfect.

① Kneader Banbury+Single screw extruder

② Kneader Banbury+Twin screw extruder

③ Kneader Banbury+Two stage extruder

Banbury compound:

1.The plastic kneader adopts an automatic temperature and time control system.

It is accurate, simple and easy to operate, and the mixing can achieve the best uniform dispersion effect.

2.The mixing tank is tiltable, and the mixing shaft is leak-proof and adopts a dry mechanical shaft seal to make it easy to clean and change colors.

3.The pressurized kneader(Banbury) can not only ensure the mixing characteristics and quality, but also prevent environmental pollution.

4.plastic knead mixer(Banbury) of the internal mixer is made of high-grade alloy steel, and treate surface with wear-resistant steel.

Electroplate surface with hard chromium and has excellent wear resistance.

The separate functions of the upper and lower extruders.

And the operator can perform a more flexible and predictable mixing process and temperature control.

5.When the material passes through the single screw, release pressure of the material to the maximum.

And the material is uniformly and stably extruded through the large screen changer in the head to ensure the long-term stable quality of the material.

Tag: Kneader Banbury mixer, plastic kneader, rubber kneader, extruder kneader, extruder banbury, plastic Kneader Banbury Mixer

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD