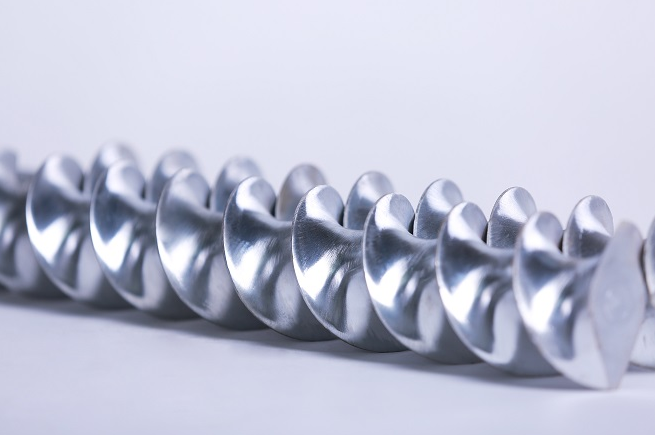

- Main categories: Plastic extruder/ Barrel and screw/ Die head/ Extruder mould/ Supporting machinery

- Service tel:+86 15251884557

Common parameters of twin-screw extruder

1.”D” : screw diameter, is the core parameter of twin screw extruder, usually according to the definition of the model; Domestic mainstream models screw diameter D mainly includes: 20mm, 35mm, 50mm, 65mm, 75mm, 95mm; The third generation model developed by Nanjing Keya, screw diameter D: 26mm, 36mm, 53mm, 63mm, 73mm, 96mm, 125mm, 135mm, this series of models screw diameter large and small diameter ratio is unified, can achieve the same production conditions, model amplification effect.

2.”L\D” : screw length and screw diameter ratio, usually called “length-diameter ratio”; This parameter directly affects the plasticization degree of the material and is an important sign to measure the material process suitability of the twin-screw extruder. General polymer plastic modification operation, length-to-diameter ratio D/L between 28~48, special process L/D can achieve 68 or larger, Nanjing MQ development of ultra high molecular weight polyethylene special twin screw extruder, meltjet material special twin screw extruder, silicone glue special extruder and other special materials are using large length-to-diameter ratio process.

3.”H” : The depth of the screw groove can reflect the size of the material filling space in the screw. Nanjing MQ developed HKV series of deep groove models to meet the broader material process needs of users, and won a good market reputation.

4.”N” : In recent years, the international development trend of twin-screw extruders is high speed. Domestic conventional manufacturers mainly use 600rpm twin-screw extruders. Nanjing MQ took the lead in developing and introducing the first domestic model with the main engine speed N up to 900rpm in 2011. The third HK series twin-screw extruder has become the mainstream model in China. After nearly 10 years of efforts, Nanjing MQ has achieved the R & D, design and manufacturing capability of the main engine speed of 1200~1500rpm, and has successfully delivered to customers for stable continuous production.

5.”P” : motor power and heating power, usually reflects the energy consumption of twin-screw extruder. Nanjing Keya latest research and development success, new heating system, can effectively reduce energy consumption, the same working condition, energy saving 33% (details refer to “website article Keya high precision temperature control system upgrade! Small power consumption! Heat up very fast! You’re an old twin-screw extruder

China ©2024 Nanjing MQ Extrusion Machinery Co. LTD